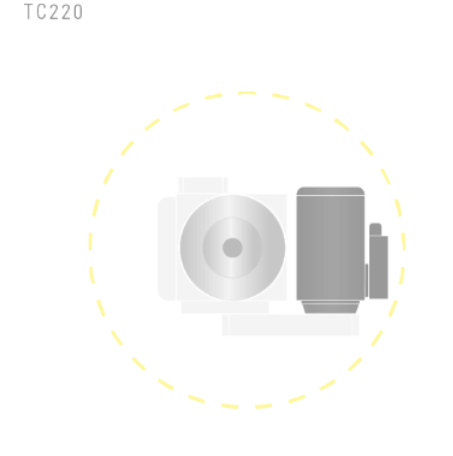

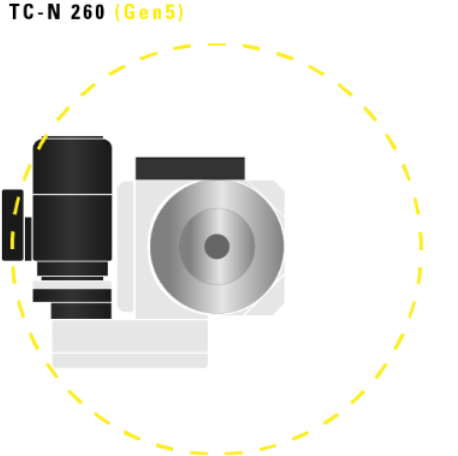

With the fifth generation of its rotary indexing tables, WEISS is now taking a further, resolute step towards fulfilling customer wishes for more flexibility, resource efficiency and speed. Moreover, the series of products creates easy access to production digitalization for system integrators, plant manufacturers and users.

Smaller size, higher cycle rates, more loading, more compact overall systems. The new bearing arrangement and redesigned drive train increase the dynamics. The flat, compact rotary indexing tables achieve high rigidity and robustness. In the future, users can resort to a smaller size so that higher cycle numbers can be achieved at the same load.

Find out more

Find out moreA reliable mechatronic component is the basis of productivity, efficiency and digitalization. The technological basis of the WEISS rotary indexing tables was completely revised. The new mechatronic platform combines a rotary indexing table, motor, control and future digital functions. It can be seamlessly integrated into an overall system.

The focus of this product redesign is on the user. Each adaptation and optimization is geared toward achieving faster production times, a higher throughput of parts, improved utilization or a more efficient use of resources. The mechatronic concept of the rotary indexing tables has been completely revised. With the fifth generation, WEISS is laying the foundation for large-scale digitization. This modular design of the product range allows WEISS to deliver its customers a high degree of flexibility for optimum adaptation to their specific application.

Shorter production times or turning out larger quantities in the time available help boost productivity and thus the output. At the same load, the fifth generation of WEISS rotary indexing tables is up to 38 percent faster. To allow a higher load, the axial force increases by a factor of 2.

In modern production processes, productivity is not the only thing that matters. Existing resources must be used strategically. At stake here is how to make best use of the work time, materials and financial resources. With the fifth generation, the total rotation time is reduced by up to 25 percent. Engine efficiency is up to 27 percent better.

Modular automation systems can be converted to meet changing requirements in an extremely short time. Each component of the overall system adds to this flexibility. The fifth generation offers users five configuration options for motor and gear unit. Together with the motor and control unit, the gear unit is now almost infinitely variable with eight stages.

Connecting production and automation processes to create a network can prevent unnecessary downtime. Feedback from each machine component to the higher-level system establishes transparency, enabling access to even more optimization options. Virtual models support plant design and commissioning.

The mechatronic foundation of WEISS rotary indexing tables is ready for your task. Only when the component fits seamlessly into the overall system and is reliable and precise, increased efficiency and digitization are possible. Controls, interfaces, virtual models and digital tools all play important roles.

These are exactly what WEISS offers. Want to learn more? Simply schedule an appointment.

If you have any questions about Gen5 please contact us at the following e-mail address sales@weiss-world.com

Discover the performance features, benefits and a study on the increase in productivity due to the new rotary indexing tables in a concise and clear summary.

The video clearly summarizes the features and optimized aspects of the fifth generation of WEISS rotary indexing tables.

Digitalization is changing our environment and our industry. Automated processes will be mapped digitally in the future. But digitization only brings real added value when the right foundation has been laid.

At WEISS, we see the mechanics and mechatronics of our components and solutions as the cornerstone of meaningful production digitalization. That is why we have revised both the mechanics and the mechatronics of the fifth generation of WEISS rotary indexing tables, improved them, made them even more reliable. So you can face the coming changes in a positive and successful way thanks to a future-proof production.

Change is not the question. It is the answer.

The fifth generation of WEISS rotary indexing tables!